MIDEXX™ TraceabilityMID breakthrough color management technology to track color consistency and manages accuracy from batch to production. Trace from the source to the end products, and get complete insight into your Product Genealogy.

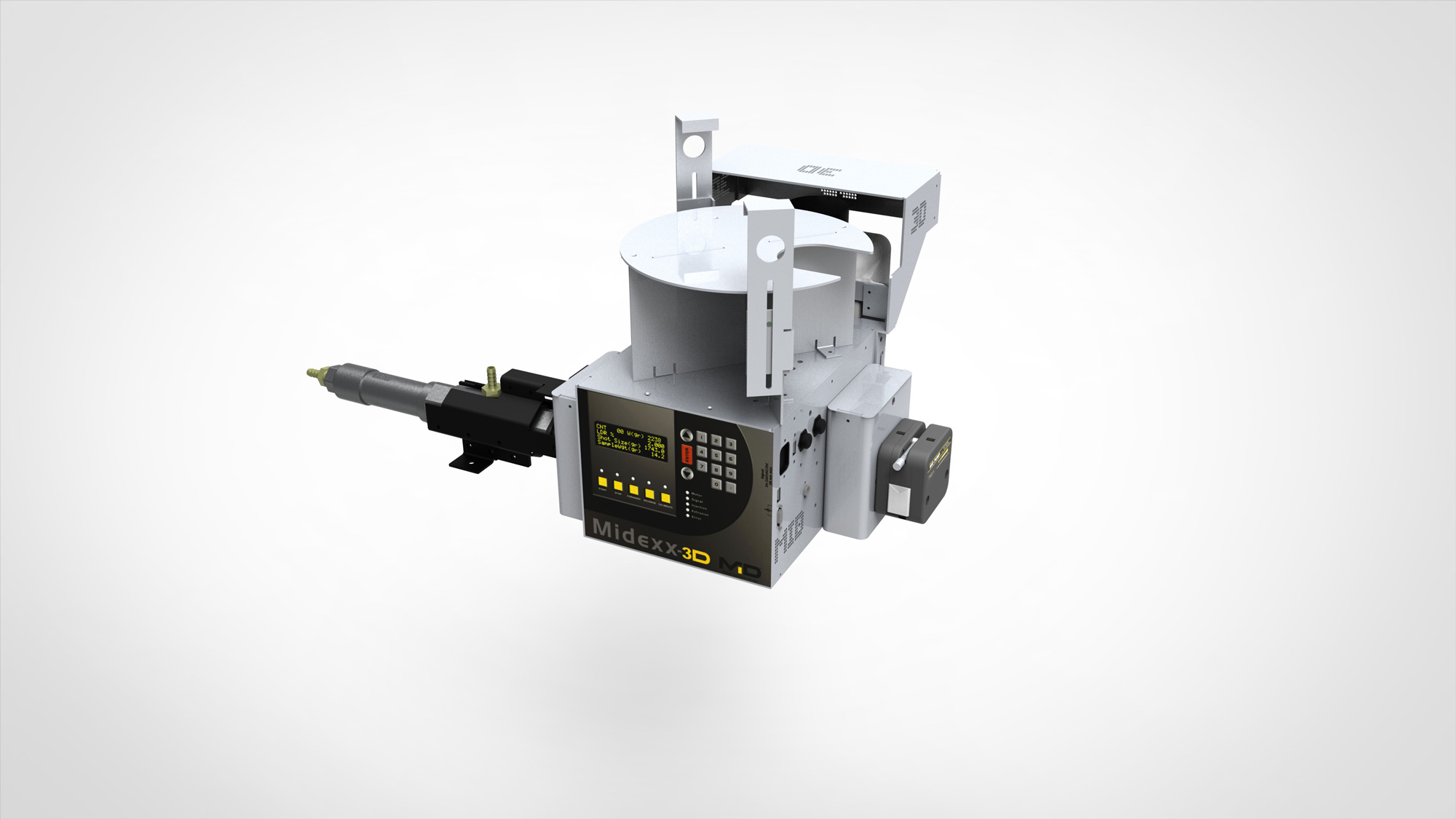

MIDEXX™ Traceability is the latest milestones in MID’s quest for excellence in control and automation solutions for the plastics industry. The breakthrough color management technology could track color consistency and manage accuracy from batch to production. MIDEXX™ Traceability uses radio-frequency identification (RFID) chip to identify, transmit and match color information, which helps eliminate any human error for minimum reject parts and maximum accuracy and efficiency in any color dosing application, especially for industries of pharmaceuticals, biopharmaceutical and food.

Color Validation

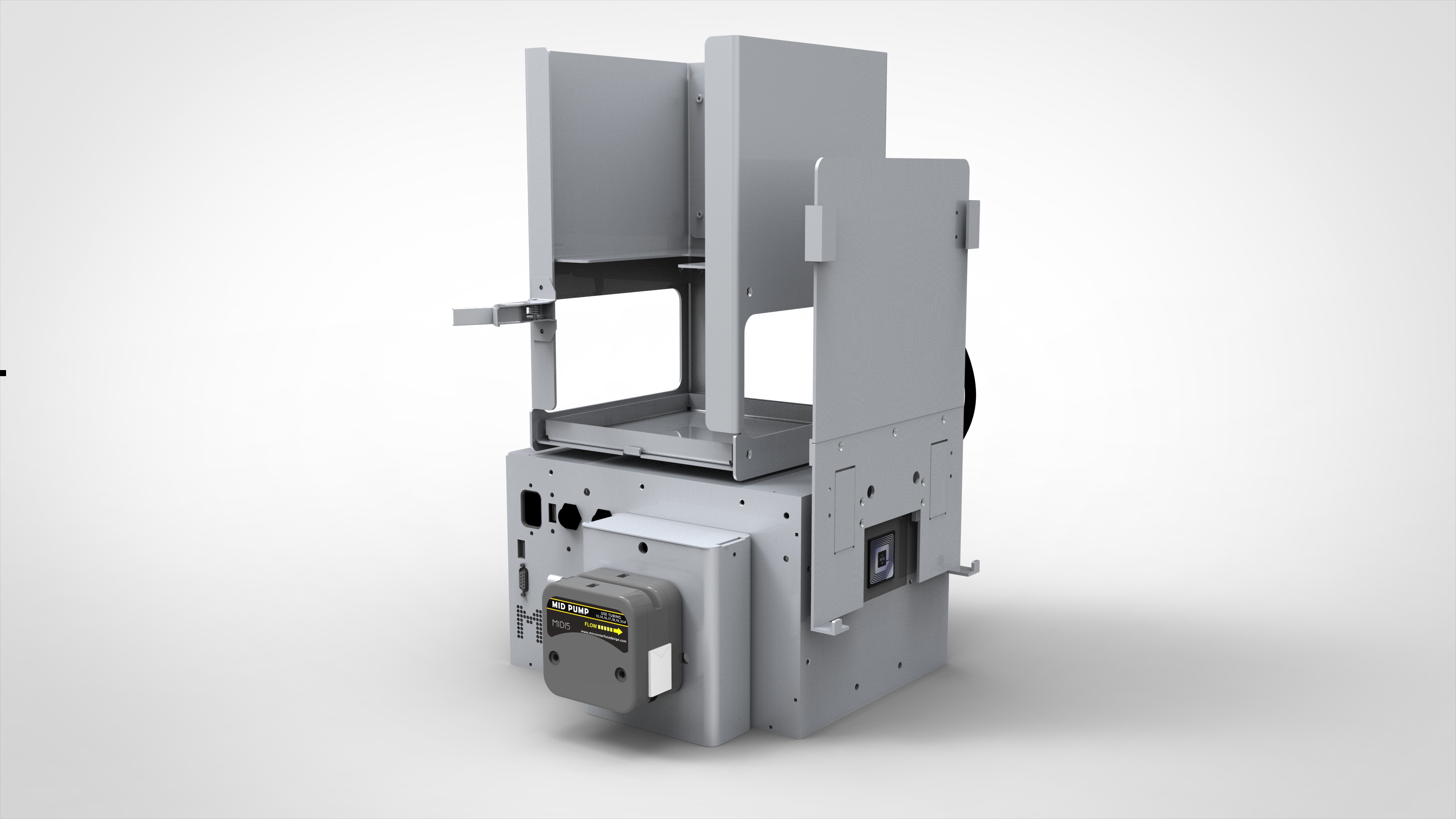

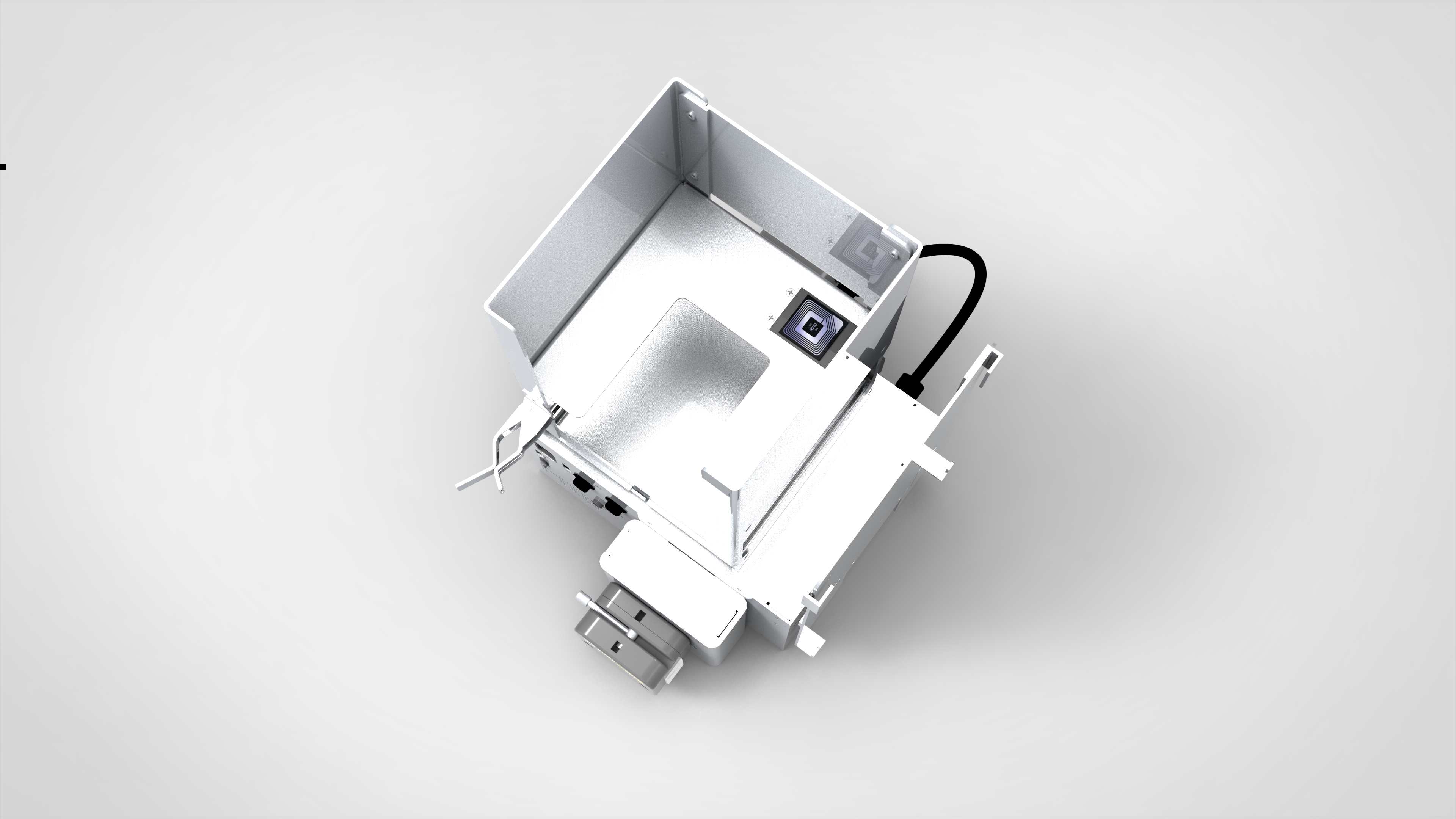

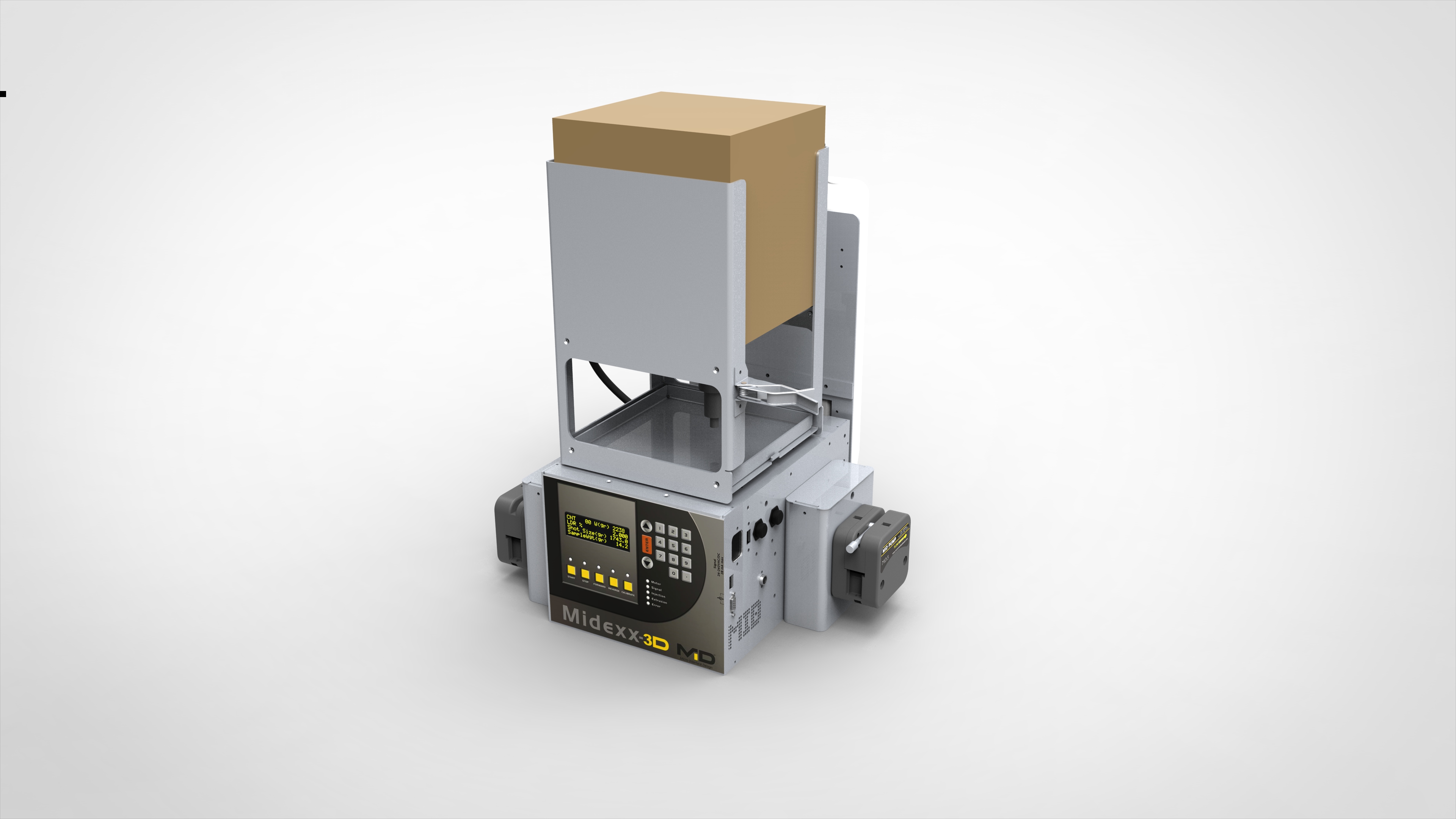

The MIDEXX™ Traceability is built on MIDEXX-3D system equipped with RFID Technology. The RFID chip identifies color information from the color container and match with the preset data. Reservoirs will reject to re-fill unmatched colorants and provide error alarm, eliminating any possible human errors and keep your process precise and accurate.

Product Genealogy

Get insight into your product genealogy is that simple. The RFID chips could identify the data from tags and provide complete information of the raw materials for your finished products.

Track Material Usage

Get full control over your application right away. MIDEXX™ Traceability provides real time data on material usage during every liquid color dosing process, improving the efficiency and preventing possible material shortage or wastes.

Build MIDEXX™ Traceability upon MIDEXX-3D

For continuous liquid color dosing with traceable materials.